PriceWaterhouseCoopers (PWC) published its annual review of the Forest, Paper and Packaging industry in January 2010

Named “Forest, paper and packaging: CEO perspectives <of the year>”, PWC is doing quite a challenging annual job. And every year the report is coming up with astonishing intimate insights. But let us have a closer look to the latest report (the 2010 version):

Putting important things first, we highly recommend to read this article first...

Ready? Got the message above? OK - go further...

Firstly I will cite some statements taken from the report:

|

“This kind of modification [to company business models] is based on the market demand; we maintain close communications with our partners on customer needs to strive for mutual development and benefits.” “What differentiates us from others? It is quite simply that we deliver the right product, at the right time, at the right price, to our clients.” “Differentiate yourself from the commodity business and impose yourself as a service provider, it’s so important.” |

PWC has summarized those statements like this: “Most CEOs also already recognize the need to take the customer’s wishes more closely into account.”

When reading those statements and the conclusion of the study authors – what is your feeling?

Honestly.

I tell you my impressions: How can these statements are done by CEOs of an industry which is in business since centuries? Forest, Pulp and Paper – this is a business which operates since mid of the 18th century.

And they are still thinking it MIGHT be a good idea to produce products which are demanded by customers?

Keeping close communication to partners and customers seems to be a big advantage to them?

Just to remind you: this is not a virgin industry like IT or telecommunications – no, we are talking about a mature industry – the paper & packaging industry. I would have expected an industry like this would have had enough time to fix the basics at the lowest level. But when reading those statements one might think: “What the hell did they have done the last 50 years?”

But let us go further. There is more interesting statements within the report:

| “Over the past two years, we have focused on not only surviving but thriving from the economic downturn. That includes reducing fixed and variable costs, improving productivity and controlling working capital.” |

Frankly speaking, this is basics as well. This is not worth mentioning explicitly. One could argue these basic business rules have been spotted by the industry just recently and haven’t been known even before. This might have been a good idea doing so even without facing an economic downturn.

Well, all those statements might have taken out of context and I am doing them wrong. Because ignoring these basic business rules would have lead to an immediate withdrawal of any license to operate. Furthermore, any CEO would have been kicked out of the market in no time at all. Surely.

But let us go further in the report. There are other interesting topics as well:

|

“We heard a strong consensus from CEOs that the FPP industry needs to do a much better job at raising public awareness and understanding of the fundamentals of the business. The industry must improve its ability not only to publicize its successes in increasing efficiency and reducing carbon emissions, but also to convey the realities of modern sustainable forestry and pulp and paper-making processes.” “Virgin fiber based carton board is the most sustainable, most environmentally sound packaging application and we are very confident that the total demand and consumption of those packaging materials will very strongly increase also in the future.” |

In general all these statements are right. Virgin fibre – wood in simply terms – could be an environmentally sound raw material - but is not innately and by any means. As long as there are companies which are supplying their demand from old growth rain forests (e.g. Pindo Deli) the industry will face hard times to proof their products environmentally sound. However, there are a lot of paper companies which have invested quite a lot in environmental sound production and wood supply from sustainable sources.

But all these efforts will not come across as long as some rotten apple will do their sordid business at the expenses of the integrity of the environment. Once a company is blamed for its operations – the whole sector will suffer. Initiatives like “two sides” will hardly be able to compensate the damage caused to the sector by one black sheep only… Furthermore industry has to think about the style on how it will proof it selves environmentally sound. People react quite sensitive when development of genetic material is mentioned by an industry. Nowadays people will not accept operations as environmentally sound as long as genetic engineering is part of these operations. Even the use of clonal material for timber plantations is problematic. Environmentalists criticize the loss of biodiversity when using clonal material – industry should know these kinds of problems. But do they?

Another statement taken from the report:

| “Increasing the fibre yield from existing forests will also play a role in helping the industry maintain competitiveness, such as… other executives point towards Brazil as leading the way, particularly in terms of developing genetic materials to increase yield” |

But let us go further and discuss the next topic:

| “CEOs believe that too many laypeople still see the industry as a major polluter, when in reality the overall environmental impact is significantly less than is popularly believed. Notions that paper production destroys the rainforest are also widespread, even amongst opinion setters. The industry needs to work on improving its reputation as a leader in technology improvements that reduce its impact on the environment. Sourcing fibre from sustainable forests and minimizing the environmental footprint are common objectives of the industry. Improvements over the last decade have been significant but more education is still required to change the public perception…. Better PR is urgently needed. Some executives also believe that efforts are also needed to provide more information around particular products.” |

Right once again – there is misleading information about the industry spread all over the globe (e.g. just one example of many - read here). But there is many other industries facing the same problem of being recognized as not being environmentally sound. However, it seems some of them have found a way on how to tackle this problem. An article is titled: “Why being green is smart”. The author writes: “Smarter use of raw materials and energy, and producing less waste, can lead to quick improvements at the bottom line. The motto “make more by using less” has been adopted successfully by big chemical companies like BASF, Bayer and Dow”. This brings us to the question: “What are companies like BASF and Bayer doing differently to be able to proof themselves more environmentally sound than any paper industry?” And this brings us to the gist of the matter.

Forest products industry is one of the high potentials for coping with the challenges of our future. Economic downturn and climate change are demanding a new global business model. People are naming it the “biobased economy”. The forest products industry could be one of the main pillars of this new economy model. The renewable source wood was, is and will be the main raw material for this industry. However, the challenge of the future is to make more out of wood.

More in case of

- building materials (for any type of housing and construction)

- more in case of combined heat and power supply and

- much more in any type of unfinished goods and fuel

This all begins with forests. First of all wood must be raised in well managed forests. Sustainable forest management (SFM) provides us the capability to proof wood to be an environmentally sound raw material. But SFM by its own is just one side of the coin. The further use of the wood is the other side. Combustion of wood for instance has to be the very last step within the supply chain. Only when all other usages have been applied wood should be burned.

This is why we have to apply intelligent, modern and efficient production technology to maximize the advantages of wood once it is harvested.

The pulp & paper industry (PPI) is supplying its demand directly from forests and/or from the wood working industry. With some minor exceptions, the PPI is currently utilizing just 50% of the consumed wood for goods (pulp - cellulose) production. The other half might be used for energy production (as long as the mill is an integrated one which is able to use the steam for heating the paper machine) or is simply destroyed.

This is where a new magic comes into the game: Biorefinery. As wood is made up of a broad variety of different (highly valuable) components it could be used for an astonishing multitude of value-added products for the chemical industry. Biorefineries will do this magic. But there is no need for establishing a new sector of industry. The PPI can transform it selves to Biorefineries. As it is the only industry which is currently utilizing wood on a chemical base it just has to be a little flexible - simply spoken. Of course there is more behind than just adapting the industrial production processes. There is new markets, new customers, new supply chains and a lot of more.

However, the PPI can call two big competitive advantages its own:

- the knowhow on how to handle, manipulate and treat wood. Either before or within the industrial production processes

- the increasing use of renewable raw material in substituting crude oil

Is the PPI aware of this and is it preparing it selves to seize this chance? Just let us have the CEO’s say:

|

“So we’ve taken a very simplistic view of saying let’s get the broad basics right. If that’s right you can optimize around the fringes. But if we’re going to spend all of our life trying to optimize around the fringes, the broad base is going to fail. So I would say from the industry point of view it is still about getting back to basics. You know, keeping it simple.” “I think the first thing is capacity consolidation. ...I think there’s an over-capacity, everybody knows about it, and it’s not on the graphic side only or on the packaging side only, it’s on both.” |

Doesn’t sound like? It sounds much more like: “We have produced paper in the past, we are producing paper nowadays and we will produce paper till the day hell freezes over.”

So what is PPI industry doing? As far as I have learned from press, PPI can be put into following categories:

- a few visionaries

- some waverers

- and a lot of laggards and the ignorers

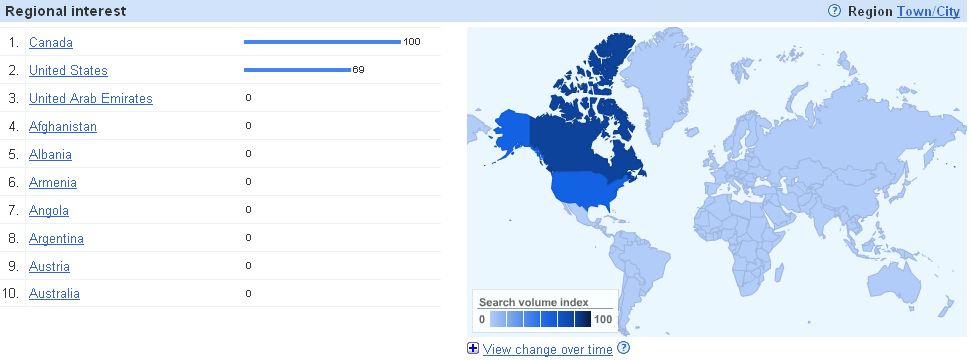

Do a Google search and you will find people talking about the concept of a biorefinery since ~ 2003/2004. Even more interesting is to do a Google Insights search – you will discover just North America being really interested in this topic.

|

|

Picture taken from Google Insights with search term: biorefinery |

Although a lot of European articles can be found most of them are related to research and development. When taking a closer look to the search results some interesting details can be discovered. It seems European Industry is spending its money and the money of the taxpayers (read here) for research and development when North American Industry is just operating biorefineries.

Also very interesting: It is not the Stora Ensos, the Weyerhaeusers and all the other big names, who is operating biorefineries.

It is outsiders like the example of Lynn Tilton. Being a former investment banker, Lynn Tilton is currently CEO of a private equity firm managing $7 billion in assets. She decided in 2008 to jump into the pulp & paper business and has therefore bought Old Town Fuel & Fiber in Maine (read the whole story here).

This might cause considerable amusement to some of you “Old Town Fuel & Fiber” – eh?

Ok – just classify yourself – visionary, waverer, laggard or ignorer?

Forestry Investements - read some interesting article here►...

And some interesting info regarding real innovations here► and here► and here►

RISI also came up with an interesting article►

Editors Note: Years after we have wrote this article - read a RISI-Blog called: I have seen the future

December 2012: EU Awards NER300 Technology Grant for UPM’s Biorefinery Project in France ... Read further here...

---------------

Survival of the fittest – also true for the forest, paper and packaging industry?