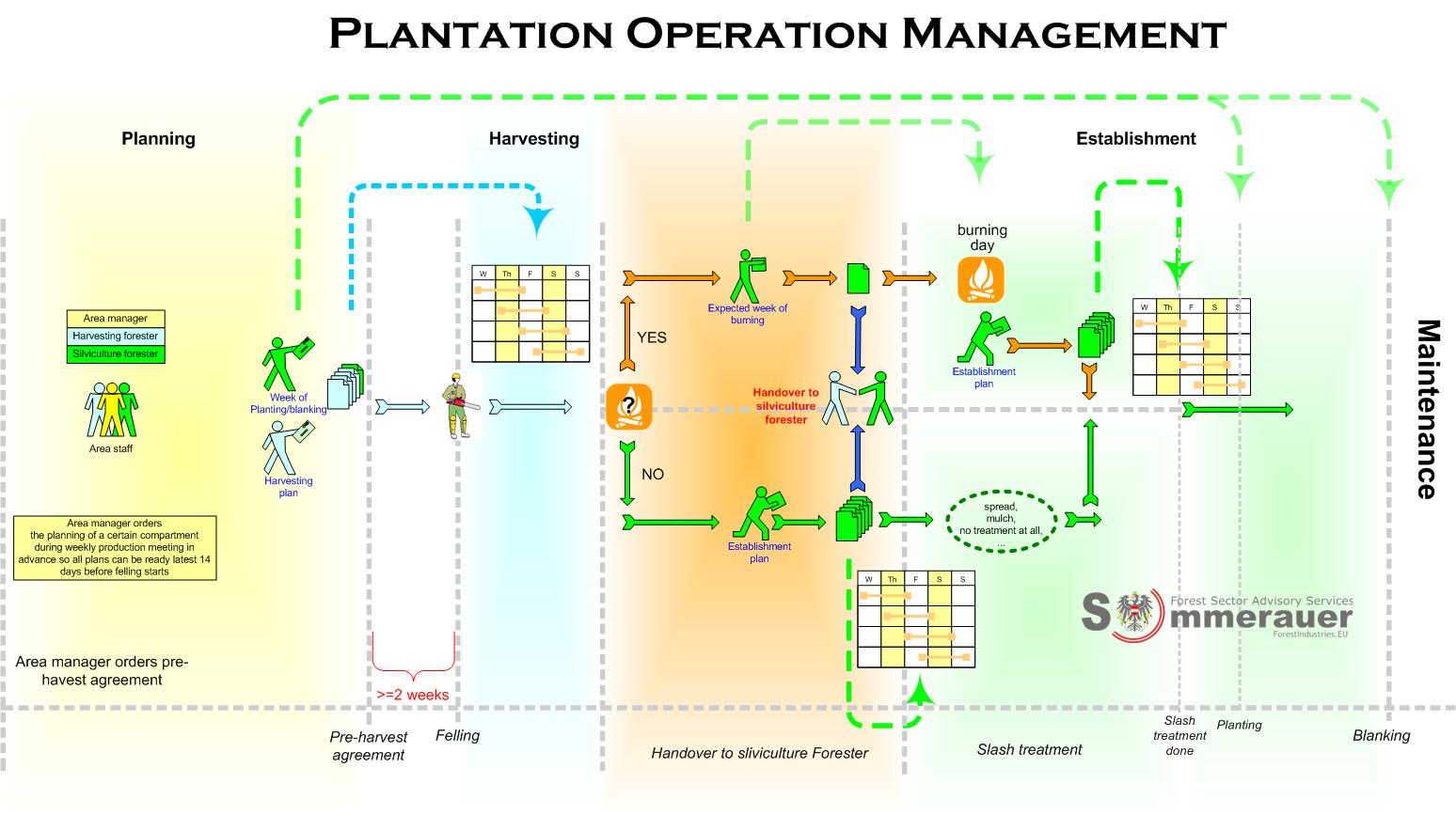

Managing Plantation Operations

From Establishment through Maintenance to Harvesting

Operations management is concerned with managing the resources that directly produce the organization’s service or product. The resources will usually consist of people, materials, technology and information but may go wider than this. These resources are brought together by a series of processes so that they are utilized to deliver the primary service or product of the organization. Thus, operations is concerned with managing inputs (resources) through transformation processes to deliver outputs (service or products).

Planning, controling, monitoring and post-costing of any plantation operation is essetial to any forest plantation management system.

We have therefore developed a sophisticated managment system - which gives any forest plantation operator the opportunity to improve any of his operational tasks.

The process includes

Establishment - Maintenance- Havesting

and measures DAILY productivity of all in-field, primary transport and depot operations. Management will therefore get exhaustive information about all relevant productivity measures on a daily base (tons over weightbridge measures remain but will play aless important information role).

Our Operations Planning System is build up by following three main parts:

- Execution Planning

- Montioring

- Post Execution Costing

.jpg)

Main objectives of our system are:

Increase transparency

- Make operations information visible to management on different levels to enable fact based management of the overall value chain

- Eliminate obvious inefficiencies that are covered by current intransparency

Standardize and simplify

- Provide a format that enables easy understanding of available information in operations for everybody

Close gaps in tight controlling of contractors

- Assurance that customer receives the services that are paid for in every operation

- Assurance that service providers are competitive regarding performance and prices

Improve knowledge base on ongoing operations

- Enable better understanding of supplier’s business

- Make knowledge transfer easier based on standard terminology

- Improve overall fact base with regard to operations to enable more and better informed decision making

Reward individual performance

- Base performance management on standardized and measurable performance indicators

Reduce costs

- Use all of the above to continuously increase efficiency of operations with the target to reduce operating costs