From pulp and paper to helicopter fuel!

-----------------

BRUSSELS, April 19, 2010 (RISI) - From Howard Hughes' helicopter company (now MD Helicopters) to Rand McNally maps, fashionable Stila cosmetics, a firetruck maker, and yes, Maine's Old Town Fuel & Fiber, New York-based financier Lynn Tilton, CEO of Patriarch Partners, is rocking industry - even old-fashioned pulp and paper. If that's not enough, she just announced a plan to retool American manufacturing with a public-private investment program. "End the capital void that has trapped small and middle-market companies and a better America emerges,"

says Tilton.

Turnaround experts since 2000, Patriarch Partners directly invests in troubled businesses, managing funds with over $7 billion of equity and secured loan assets. It has equity investments in more than 70 companies, and controlling interests in approximately two-thirds of these.

Tilton stresses that their core focus is undervalued companies where time, capital and sound strategy can rescue these businesses and restore value, often preserving jobs, while simultaneously providing demonstrated returns to investors.

Their philosophy combines innovative financial models, restructuring techniques and the operational expertise necessary to rebuild businesses facing complex situations.

In the case of Old Town Fuel & Fiber, a new revenue stream from pulp - namely bio-butanol - could be fueling Tilton's helicopters, as well as putting the media spotlight on trees as an alternative to oil.

What do the aforementioned companies such as Rand McNally, MD Helicopters and Old Town Fuel & Fiber have in common? These companies were all faltering when Tilton, came to the rescue.

You can't help but notice Tilton, whose shining personality, combined with bright ideas about industry, and finance, is working wonders on the business media, and in fact, keeping and creating manufacturing jobs.

From her success in getting MD Helicopters flying again, followed by 70 acquisitions and now a public-private plan to finance small to mid-sized companies, she is fast becoming a towering figure in the landscape of American manufacturing.

Says Tilton, "When you buy American icons and known brands at near liquidation prices, time, talent and innovation will produce opportunities to rebuild value. My style is innate and intuitive; I see what an asset will be. I do not focus on how it appears today. A century old pulp mill in Maine set my imagination to work. An innovative partnership with the University of Maine, and a $30 million grant from the government made me believe we could turn wood into jet fuel, not just pulp."

From grounded to flying high

To better understand Tilton's acquisition of an old pulp mill on Maine's Penobscot River, a look at the former Howard Hughes helicopter company is a good starting point.

Soon after buying MD Helicopters in August 2005 for a bargain price, Tilton announced a plan to support the customer base, literally to get them flying again. The focus was parts delivery for hundreds of customers, who had been grounded for nearly two years. By 2008, Tilton put huge amounts of her own money to fund idle assembly lines.

Says Tilton, "We spent the first year losing money, without manufacturing a single helicopter, but rather gathering parts, so we could put customers back in the air. We pursued vertical integration in an attempt to bring some control to our angry supply base, moving production of 1,500 metal parts in-house, which turned out to be a very wise decision.

"Within my first days at MD I knew that vertical integration made sense, but my views drew laughter, not applause from industry gurus. But our strategy has worked, and the delivery of more than 50 new aircraft in 2008 made our success quite visible to industry skeptics.

"Controlling your own destiny improves customer support," adds Tilton. "As in an emergency our own people can work around the clock to support an aircraft on the ground. Just because helicopters are complex flying machines, does not mean that the business cannot be simplified. And I might add, reputation is built upon the difficult calls - the handling of the problems and the emergencies. The MD Helicopters brand is back and here to stay."

Shifting spiegel to the web

Tilton notes that the Spiegel catalogue business lost about 30% of its top-line sales during the latest economic downturn. She explains, "I don't expect to see any rapid pickup in the economy for at least a couple years, so we have rationalized the expense structure to meet the new revenue stream. From day one, we stopped the bleeding of cash."

Her firm is shifting Spiegel away from its catalogue business (which began in 1905), moving increasingly to the Web, which already generates around 65% of revenue.

Adds Tilton, "In this changing retail market, shopping from home, buying from infomercials and the web is the norm. When I can't sleep, I make purchases this way, even things I don't need."

Patriarch Partners is also channeling the products from other portfolio companies onto Spiegel's website and into its catalogue. Stila Cosmetics, for instance, is available through Spiegel, as are ear warmers from 180s Inc. and bed and bath products from Croscill. "We see Spiegel as a vehicle and family tree for brand building our direct consumer business," she adds.

|

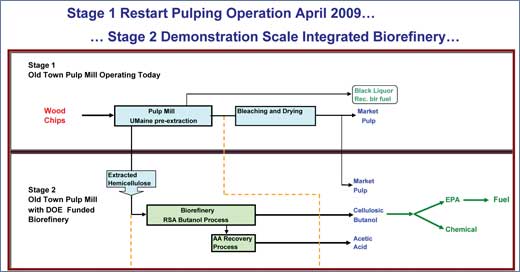

Using the “van Heiningen process”, the mill converted its existing one-vessel pulping system into a two-vessel system able to accommodate both production of pulp and the extraction of hemicellulose from wood chips. The extracted hemicelluloses are used to provide a new feedstock for fermentation to butanol. These vessels now function like two pressure cookers piped together to allow various ingredients to flow in several different directions. Wood chips are fed into the first vessel used for extraction and sluiced into the second (pulp producing) vessel. The DOE grant will allow the mill to supply hemicellulose-rich extract streams for the butanol production process, while also continuing to produce the pulp that is currently manufactured on site

|

Revving up the old mill at Old town

Lumber and pulp for paper have shaped life in Maine for more than 100 years, but more recently jobs have declined because of a shift in pulp production to South America and Indonesia. But what could happen if biofuel from cellulose becomes economically viable? It could be the fuel of recovery.

Old Town Fuel & Fiber, and projects like it, are being taken seriously, because of the potential of vast forests, not corn, becoming the leading route to alternative fuels.

Turning wood chips into a bio-fuel, basically by extracting sugars (not as easy as this sounds) is gaining widespread interest and investment.

The mill has been through various transitions of ownership. Georgia-Pacific made pulp for Northern Tissue branded products for several decades at this site, but decided to shut down. Not long after, a group of investors called Red Shield took over, partnered with the Forest Bioproducts Research Initiative (FBRI) at the University of Maine for a joint proposal and were selected for a US$30 million grant award from the US Department of Energy to work with the university on a pilot ethanol production plant. Because it takes a lot of cash to fuel development projects of this kind, Red Shield ended up filing for bankruptcy in 2008, and shut down the mill again.

But, Patriarch Partners may have completely changed the equation since it took over in November of 2008. It immediately invested $40 million, not looking at the mill as a pulp producer, but as a startup in cellulosic bio-butanol.

Says Tilton, "Bio-butanol can fuel helicopters and armored vehicles, both manufactured by Patriarch portfolio companies, and beyond that, we see that ‘trees' could prime the pump for a wide range of vehicles, a very green alternative to foreign oil. By 2022, 21 billion gallons of biofuels are the US government's target to help America become greener. We plan to be a player and active participant in this considerable market opportunity."

Concludes Tilton, "Adding jet fuel as a revenue stream will forever change the dynamics at Old Town Fuel & Fiber. I already had a vertical aviation and military hardware business structure in place, which, oddly enough, makes a fuel-producing ‘old' pulp mill an ideal fit."

Unlike "corn fed" ethanol, cellulosic bio-butanol is considered to be less corrosive and can be transported by pipeline. Having a higher energy content than ethanol, it could potentially be blended with gasoline at higher levels than ethanol without any change in the vehicles' engines.

Bio-butanol derived from wood is a way to turn so-called waste from pulp production, or from waste harvest from logging, into a value stream.

|

Overcoming obstacles

“Turning Old Town Fuel & Fiber around required a return to high productivity, and an excellent relationship with our workers. In the beginning, we knew that cellulosic fuel was years away, and we would have to survive in the meantime. But, you know, truth brings people together. We faced harsh reality soon after we bought the mill when pulp prices dropped from $500 to $250 per short ton. This left us in a position of having to decide whether or not to re-start the mill,” Tilton explains.

“I decided that we would fire up the mill, even under these difficult market conditions,” she adds. “I visited Old Town to talk with the workers and union leaders myself. First, they had up to four weeks of vacation pay carrying over. I wanted them to know that this was not in question. They had their money and we would work to advance it to them. Then, I demonstrated how serious the problems were. I showed them detailed financial information concerning wood, chemicals, fuel and labor costs, which were all high.” Tilton continues, “They understood that we could not near profitability if we did not get the price of wood down. This was not fluff. I will say now, as I did then, the possibility of closing the mill was something I could not accept on an emotional basis, although I knew I should do so on a fiduciary evaluation. Yes, an emotional basis! So as part of a plan to survive and break even during this tenure of depressed prices, I asked that all workers to reduce wages by 20%, until we could see signs of improvement and we tied the increase in repayment of past wages and new wage levels to the profitability of the plant. In fact, the vote was 170 to 10 to accept the offer. After six months the situation improved sufficiently for wages to return. Then, as a vehicle to boost productivity, I committed to a rise in wages, or a reduction, depending on results. They agreed, and they raised the bar again for productivity, and themselves. “The depth of the relationship makes Old Town unique for me in all my business dealings. Achieving greatness can happen at Old Town, which includes startup of the biofuel facility by 2012 or sooner. “We see the potential for cellulosic fuel to be a very attractive business, especially if US regulation requires its use. I don’t mean long-term subsidies, but a commitment to include some minimum amount of cellulosic fuel in jet fuel formulations.” |

Fueling a turnaround

The partnership involving University of Maine, Old Town Fuel & Fiber and its owner, Patriarch Partners, already has an advantage that was not previously in place: added capital as fuel for progress. The combined $70 million has moved the mill beyond the theoretical stage. Designing, building and operating the initial small-scale commercial biorefinery is now happening. When complete, this biorefinery will produce bio-butanol (more specifically cellulosic butanol), acetic acid and other byproducts, along with market pulp from the Old Town location. Full-scale production is targeted to start in June of 2012, or sooner.

Adds Tilton, "You could call our capital a fuel injection in sync with subject, because you have to produce and pony the money to procure the funds of federal grants." Tilton's style has also drawn a lot of media interest, which in turn attracts potential customers and partners in their project, and future expansion.

Says Dick Arnold, president of Old Town Fuel & Fiber, "Lynn does look at the bottom line, but her gut feeling is in the marketplace. She fully supports our ingenuity to be a highly efficient pulp mill, but the value streams of jet fuel and acetic acid add excitement not otherwise possible."

Comments UMaine's Hemant P. Pendse, director, Forest Bioproducts Research Initiative (FBRI), whose team is working closely with mill management as well as technical and operating staff, "Pre-pulping extraction of hemicellulose is a game changer. Once the biorefinery is in place to ferment sugars from wood extracts on a large scale, you have the bio-butanol and acetic acid revenue streams, along with quality pulp."

Pendse believes that motivated owners and workers, willing to take risks on the operating floor, are a key ingredient to reaching this bold objective. As he puts it, "Operators have allowed professors to work alongside of them, because they share the enthusiasm for being early adapters to technology which could transform the pulp industry."

Adds U. Maine's Adriaan Van Heiningen, a guru in cellulosic bio-fuels, "If Maine creates the model, and other states that share the North Woods -Vermont, New Hampshire and New York - duplicate the efforts, the impact could create jobs on a sustainable basis in this region and beyond."

Headlines such as: "Slash Dependence on Foreign Oil. Reduce Global Warming. Reduce Emissions. Create Meaningful Jobs - With Fuel From the Forest" go a long way to attract attention to this rather remote spot in Maine.

With possible headlines like "Maine Forest Fuels 10,000 Helicopters Continuously & Creates Many Jobs," Lynn Tilton's beacon will be shining ever brighter.

Martin Koepenick, Innova, is an Atlanta-based writer with more than 25 years' experience covering the forest products industry.

![]() Pulp & Paper International is FREE to qualified subscribers. Click here to find out more.

Pulp & Paper International is FREE to qualified subscribers. Click here to find out more.

---------------